Home > Research > Research Results > Research Results 2018 > Elucidation of production conditions for glycol lignin with controllable structure and thermal properties

Update:September 11, 2018

Main content starts here.

Elucidation of production conditions for glycol lignin with controllable structure and thermal properties

| Article title |

Isolation and Characterization of Polyethylene Glycol (PEG)-Modified Glycol Lignin via PEG Solvolysis of Softwood Biomass in a Large-Scale Batch Reactor |

|---|---|

| Author (affiliation) |

Thi Thi Nge(a), Yuki Tobimatsu(b), Shiho Takahashi(a), Eri Takata(a), Masaomi Yamamura(b), Yasuyuki Miyagawa(b), Tsutomu Ikeda(c), Toshiaki Umezawa(b), Tatsuhiko Yamada(a) (a) Center for Advanced Materials, FFPRI, Tsukuba, Ibaraki, Japan. (c) Department of Forest Resource Chemistry, FFPRI, Tsukuba, Ibaraki, Japan. |

| Publication Journal |

ACS Sustainable Chemistry and Engineering, 6(6):7841-7848, May 2018, DOI: 10.1021/acssuschemeng.8b00965( External link ) |

| Content introduction |

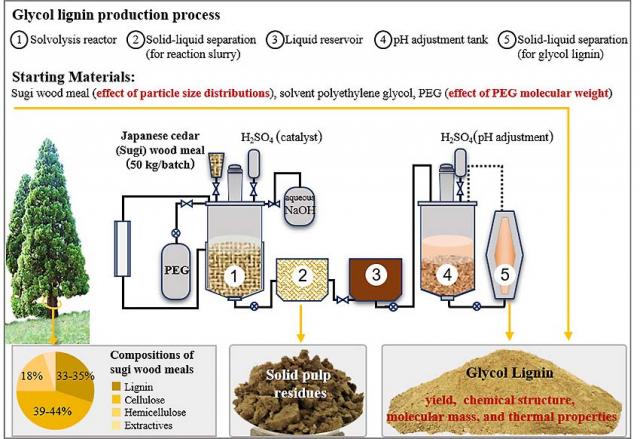

We have developed a technically feasible process for a large-scale lignin production (50 kg wood meal per batch) from widely abundant Japanese cedar (sugi) biomass to introduce technological innovation in biomass utilization systems in Japanese rural areas. Typically, the Japanese cedar wood meal with different particle size distributions, and solvent polyethylene glycol (PEG) with different molecular mass together with a small amount of acid catalyst are used as starting raw materials in our acid-catalyzed PEG solvolysis process to produce PEG-modified lignin derivatives, namely glycol lignin (GL). The effectiveness of the lignin production process was elucidated by investigating the effect of the two main raw materials; Japanese cedar wood meal size and the solvent PEG molecular mass on the yield, chemical structure, molecular mass, and thermal behavior of the GL products operating under the same processing conditions. Particularly, the chemical structure of GLs displayed the lignin linkage introduced with PEG chains in addition to typical characteristics of lignin linkages observed in softwood lignin. The efficient introduction of PEG chains into the isolated lignin polymers provided the thermal flow properties, which is a distinctive characteristic of this product. Overall results indicated that reducing the wood meal size and/or solvent PEG molecular mass enhanced the reactivity of the wood meal substrates and solvent PEG in the solvolysis reaction contributing to the highest GL yield, while increasing the solvent PEG molecular mass enhanced the thermal stability of GL. By manipulating the solvolysis conditions, such as wood meal size and/or solvent PEG molecular mass, our developed process can produce GLs with substantially controlled over chemical structure and thermal properties. This study provides basic information that is important not only for the scale-up GL production process but also for GL-based advanced material development.

|

Copyright © Forest Research and Management Organization. All rights reserved.