Home > Research > Research Results > Research Results 2020 > Speeding up the evaluation of fire-retardant-treated and surface-coated wood that is highly resistant to weathering

Update:June 19, 2020

Main content starts here.

Speeding up the evaluation of fire-retardant-treated and surface-coated wood that is highly resistant to weathering

| Article title |

Influence of moisture absorption on the degradation of fire-retardant-treated and surface-coated wood ―Effect of water spray duration under accelerated weathering― |

|---|---|

| Author (affiliation) |

Ryo Takase (a), Atsuko Ishikawa (a), Daisuke Kamikawa (a), Hiroshi Matsunaga (a), Toshiro Harada (b) (a) Department of Wood Improvement, FFPRI, Tsukuba, Ibaraki, Japan. (b) Principal Research Director (Wood Utilization), FFPRI, Tsukuba, Ibaraki, Japan. |

| Publication Journal |

MOKUZAI HOZON(Wood Protection)46(2), 80-88, Japan Wood Protection Association, Mar 2020, DOI:10.5990/jwpa.46.80( External link ) |

| Content introduction |

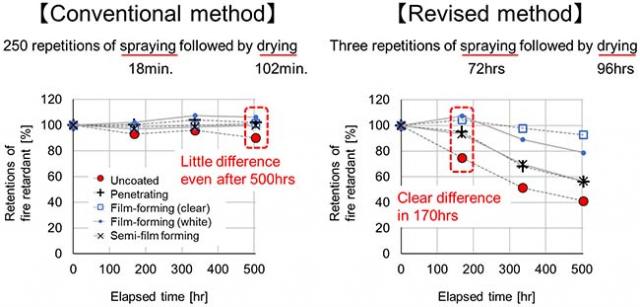

In recent years, there has been a growing need to use fire-retardant-treated wood in outdoor walls or fences to prevent the spread of flames during a fire. When fire-retardant-treated wood is used outdoors, it is usually coated to prevent the fire retardant from being leached by rain. However, it appears that the ability to protect the fire retardant depends on the type of coating. The objective of the present study was to examine a new, accelerated method for selecting coatings that can effectively protect fire-retardant materials, using equipment which artificially exposes the materials to light and water. Normally, evaluations consist of hundreds of repetitions of 120-minute cycles comprising of 18 minutes of water spraying and 102 minutes of drying. For comparison, the revised method consists of a few repetitions of a 168-hour cycle of spraying for 72 hours and drying for 96 hours. While conventional tests showed no differences in the ability to maintain the performance of various types of fire-retardant-treated and surface-coated wood after 500 hours, tests using the revised method showed differences at about 170 hours. We found that the new method could greatly reduce the time needed for evaluations. This result will help to speed up the development and promote the utilization of longer-lasting fire-retardant-treated wood for outdoor use.

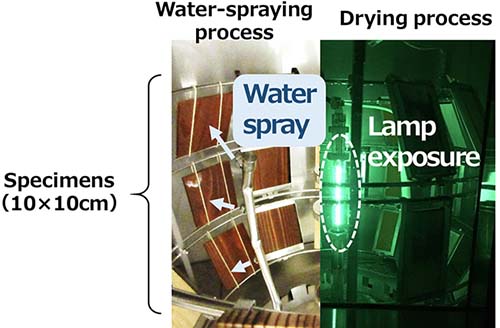

Photo: View of the set-up for the tests. Five types of chemicals used to coat fire-retardant-treated wood were repeatedly subjected to spraying with water and drying with a heat lamp to reproduce conditions that might reduce the effectiveness of fire retardants outdoors.

Figure. Differences in the fire-retardant residual rate among different types of chemicals used to coat fire-retardant-treated wood. By using the revised method (right), it became possible to evaluate the effectiveness of different coating materials in maintaining the performance of fire-retardant-treated wood in a shorter period of time. |

Copyright © Forest Research and Management Organization. All rights reserved.